Welcome STARK TOUCH DEVICE!

Optical Bonding

Our Optical Bonding Service

- Supply TP (Touch Panel) / CG (Cover Glass) + LCM Module / OC (Open Cell) Panel + Optical Bonding Service

- Supply Optical Bonding Service (Custom Touch Panel / CG + LCD Module / OC Panel)

Organic Silicone Glue (Germany Wacker)

- No yellowing even under high temperature

- Effectively prevents internal bubbles

- Prevents yellow screen phenomenon

What is Optical Bonding?

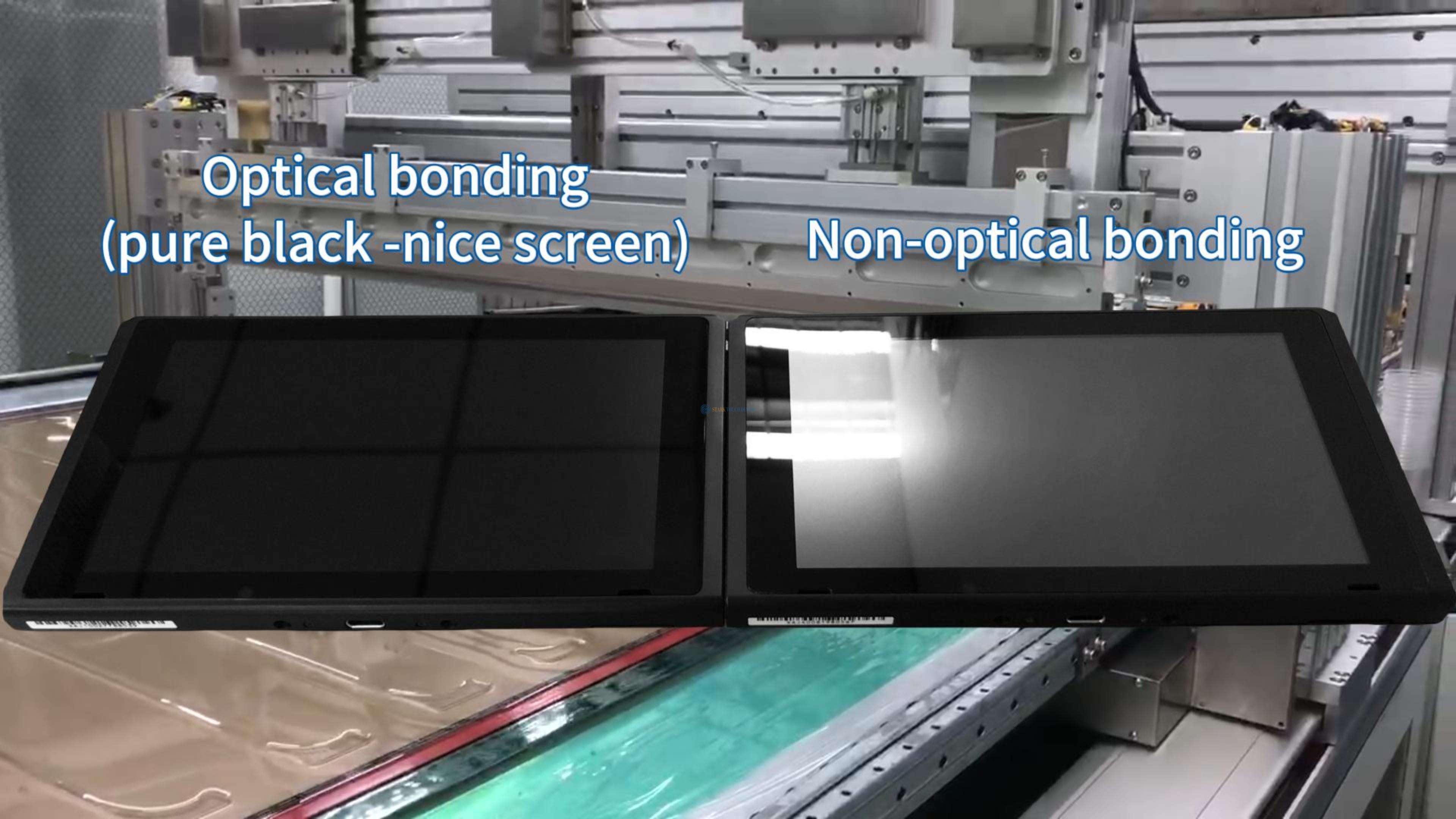

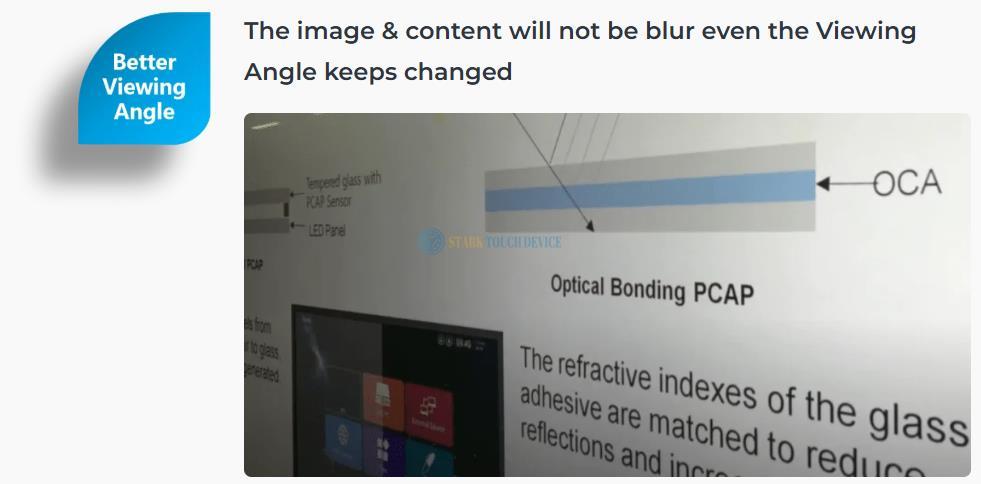

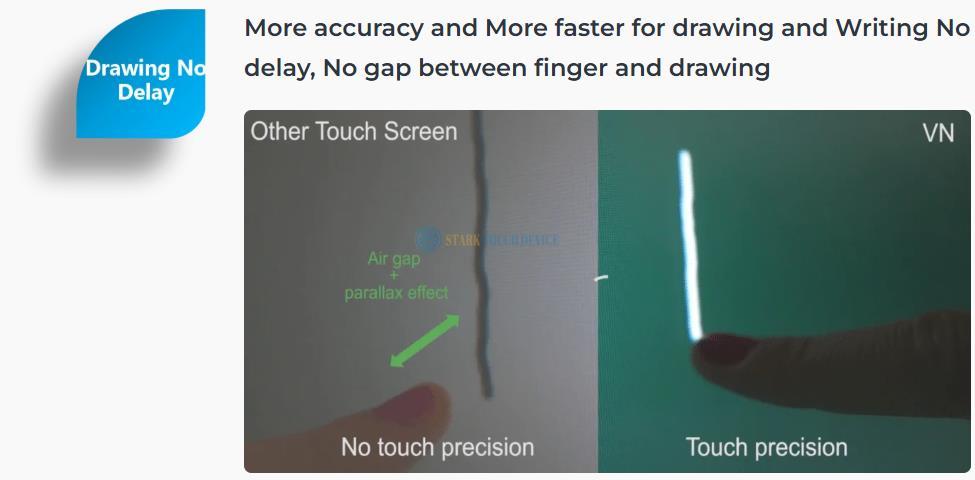

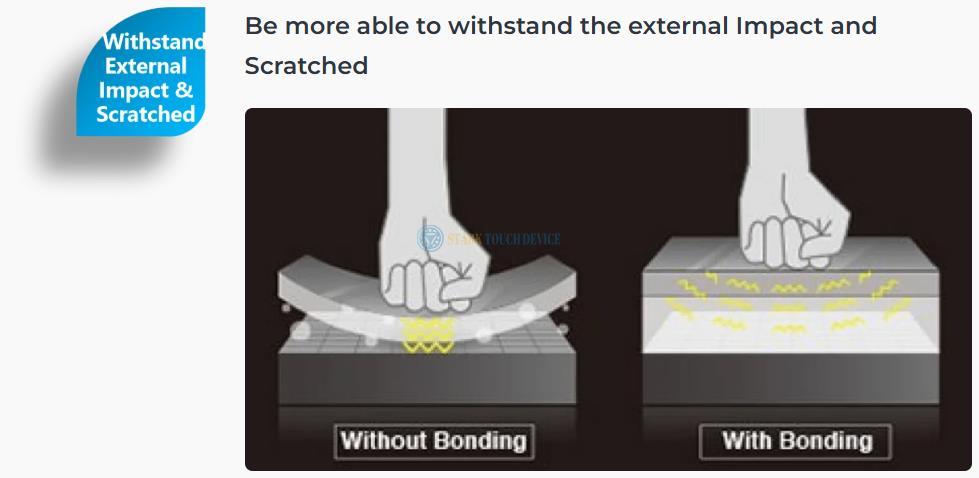

Optical bonding is a technology that uses optical-grade adhesive (OCR or OCA) to bond the display glass or touch panel directly to the TFT LCD panel, forming a solid laminate without any air gap or bubbles.

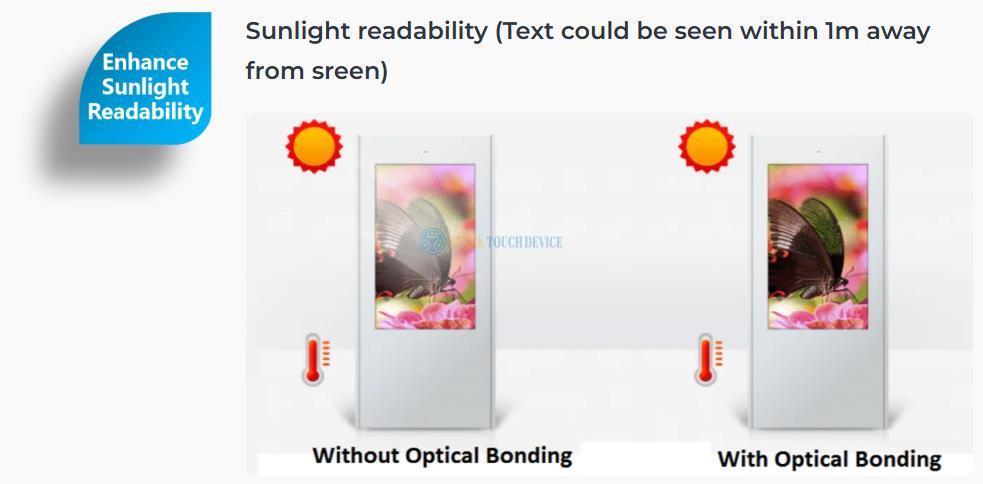

It is widely used in medical, military, transportation, retail and outdoor applications where high brightness, durability and reliability are required.

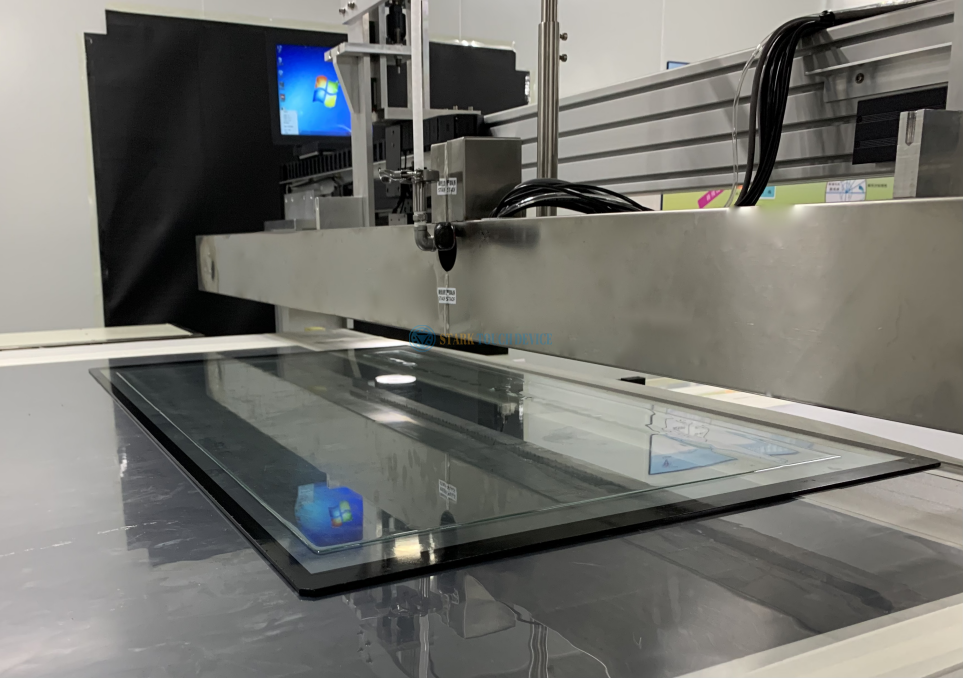

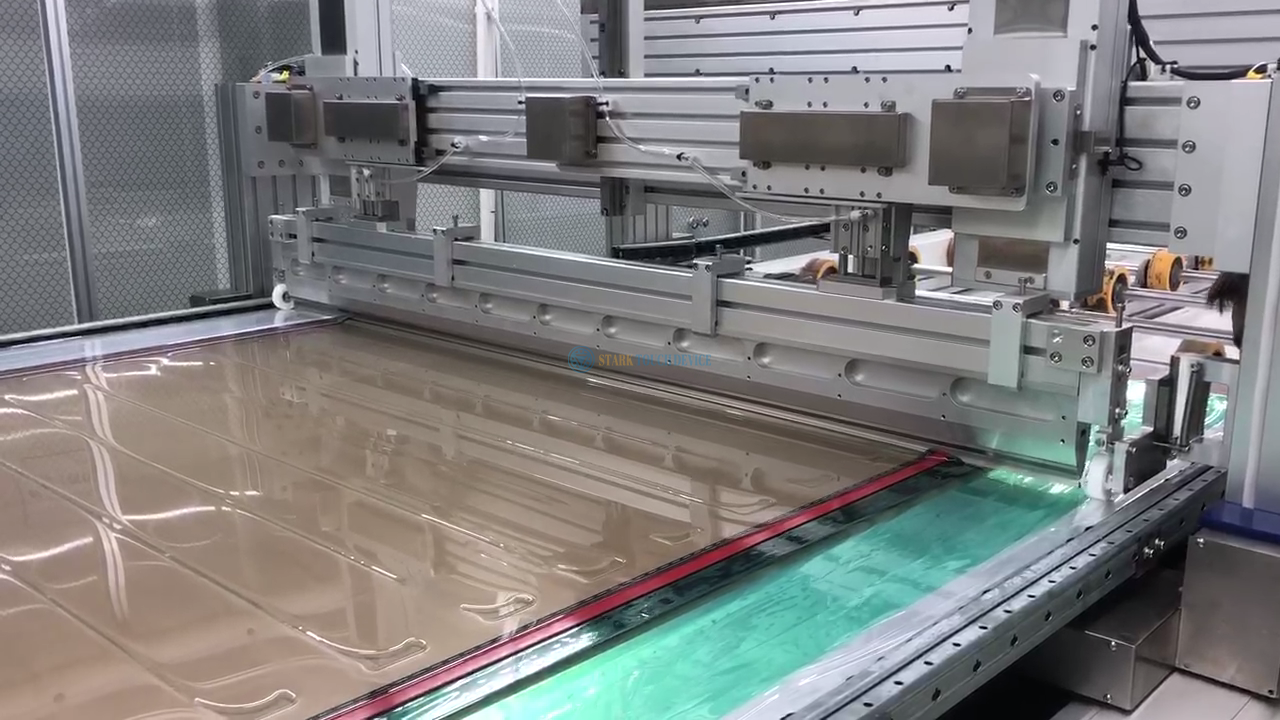

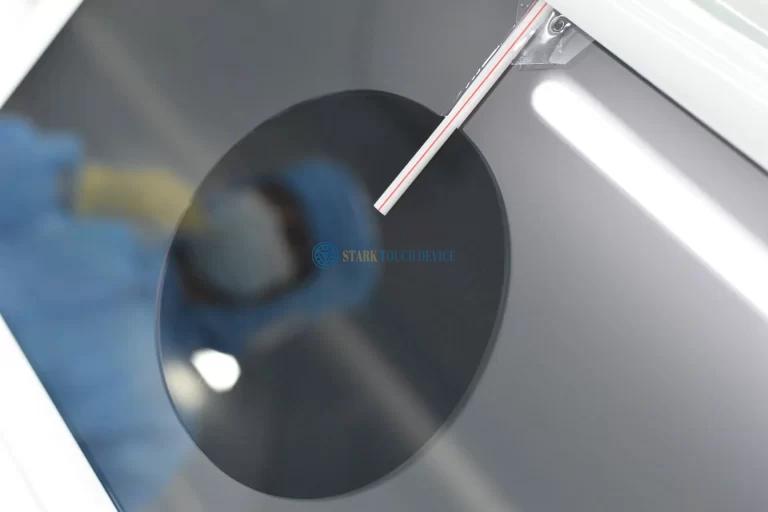

Optical Bonding Process

Our optical bonding technology improves optical performance, impact resistance and thermal management.

1. TP / LCM Inspection

LCM Inspection

a. Check for foreign objects or scratches on the screen

b. Ensure the metal frame is intact and undamaged

c. Check for dead pixels, dark spots and color abnormalities

TP Inspection

a. Inspect surface scratches and flex cable condition

b. Verify touch functionality

2. LCM Sealing Dam1. Apply black adhesive around the edges to prevent leakage during injection. 2. Cure the adhesive in an oven.

|

3. Remove Excess AdhesiveClear any excess black adhesive from the frame.

|

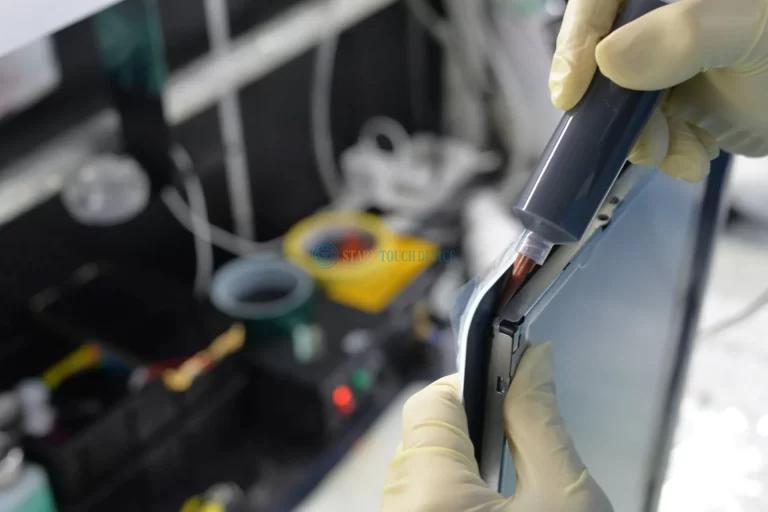

4. Inject Wacker SealantEnsure no air bubbles are formed during the process.

|

5. Seal Edges with Black AdhesiveEnhance waterproofing and reinforce the injected sealant layer.

|

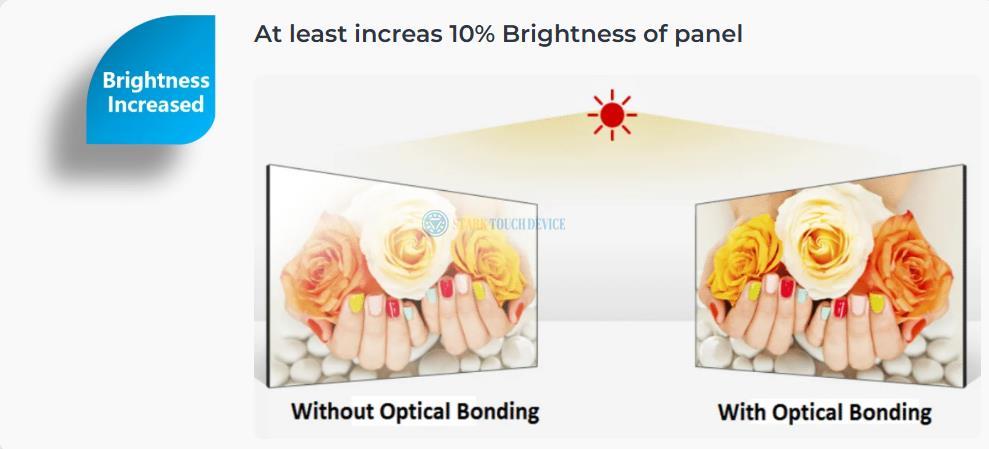

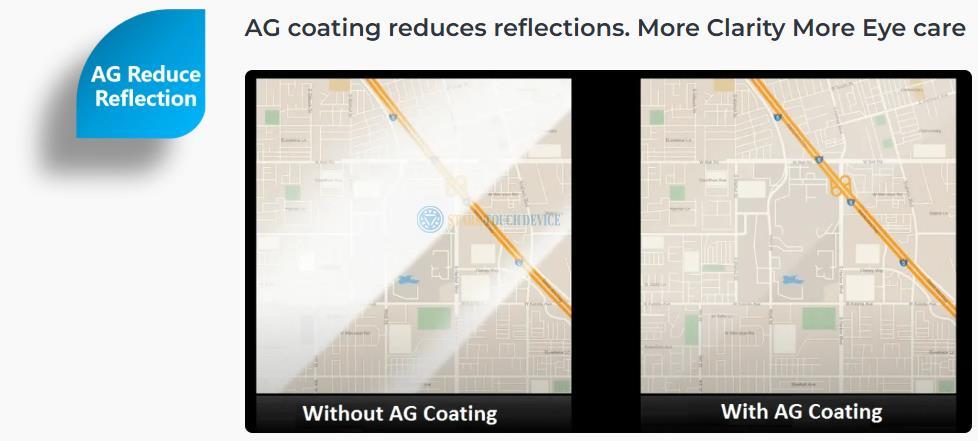

Optical Bonding VS Non-Optical Bonding

|

|

|

|

|

|