Welcome STARK TOUCH DEVICE!

Intelligent manufacturing

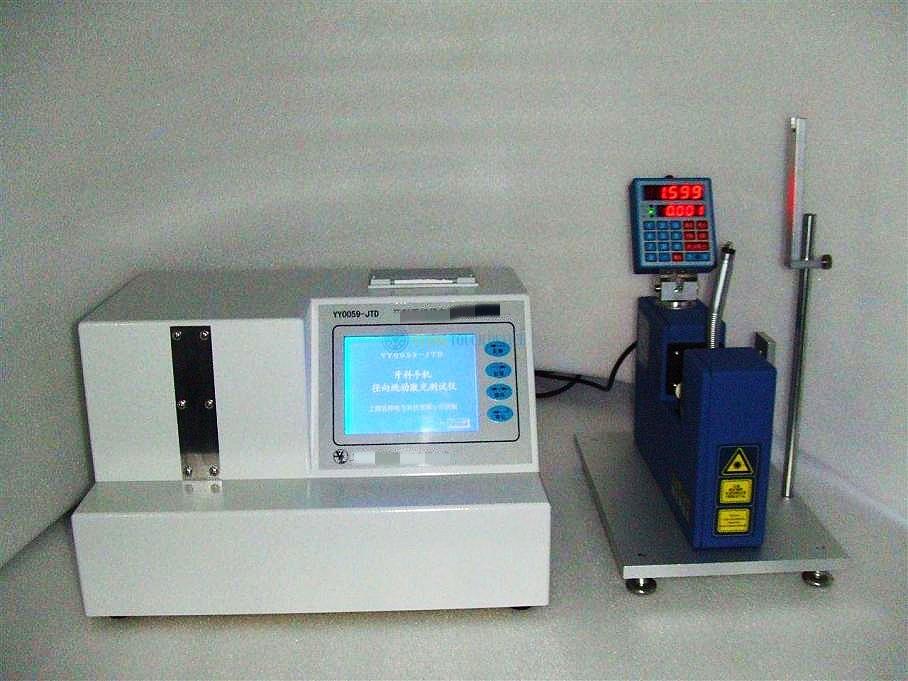

Application of Industrial Android All-in-One PC in Instrumentation and Testing Equipment

System Overview:

Instrumentation and testing equipment, born out of the necessity for industrial safety and product quality assurance, serve as auxiliary tools that encompass various detection methods to evaluate production facility performance and product quality. Widely adopted across industries like manufacturing, agriculture, transportation, technology, and defense, these equipment have undergone a transformation from manual to intelligent testing, resulting in soaring accuracy and efficiency, thus enhancing productivity while minimizing costs.

Equipment Requirements:

As precision instruments, the composition of instrumentation and testing equipment's core systems is dictated by their detection targets. Engineers input specification data and configure distinct testing programs, gather measurements, and compare them against preset standards to complete inspections. To meet these rigorous demands, the equipment must possess:

Versatility: Compatible with diverse instrumentation and testing setups.

Precision & Efficiency: Capable of executing tests accurately and efficiently.

Robustness: Cast aluminum housing for operation in complex environments.

Environmental Tolerance: Resistant to wide temperature ranges, voltage fluctuations, interference, dust, water, and corrosion.

High Resolution: Supporting multi-display on a single screen with user-friendly interfaces.

Diverse Touch Screens: Accommodating various user preferences.

Open Design: Facilitating embedded installation.

Software Development Support: Allowing customization of new testing programs based on actual needs.

Solution:

Our industrial Android all-in-one computers, renowned for their powerful capabilities and adaptability, cater perfectly to the intelligent system requirements of various instrumentation and testing equipment. With an open design tailored for internal embedding, they can be customized to fit the dimensions of diverse devices, addressing installation challenges. Offering a range of touch options, including non-touch, capacitive, and resistive, they ensure seamless operation across various work environments. By real-time data collection, fault prediction, and 100% online quality control of components and assemblies, our solution drastically reduces testing cycles and recalls, significantly enhancing both testing and production efficiency. It transcends manual visual inspection, improving instrumentation testing's speed, quality, and reducing defect rates, ultimately saving production costs.

Product Features:

Android/A64/2G+8G Configuration

Open Design Customizable to Enclosure Size

Slim Aluminum-Cast Body Ideal for Embedded Installation

Proprietary Motherboard for High-Speed Operation & Data Storage Solutions

High-Resolution Display (1920*1080) for Multi-Display Requirements

Android SCADA Software Compatibility

Versatile Touchscreen Options: Non-Touch, Capacitive, Resistive

Intuitive Graphical User Interface for Error-Free Operation