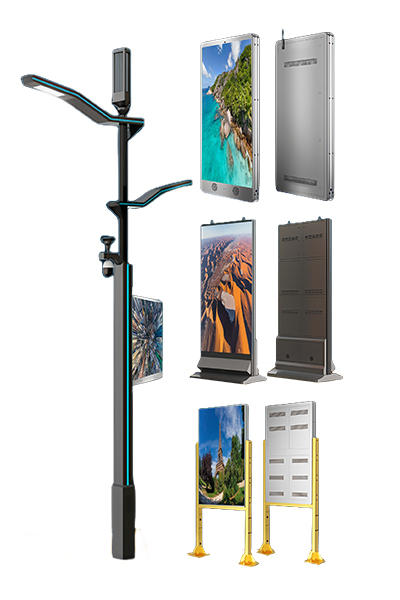

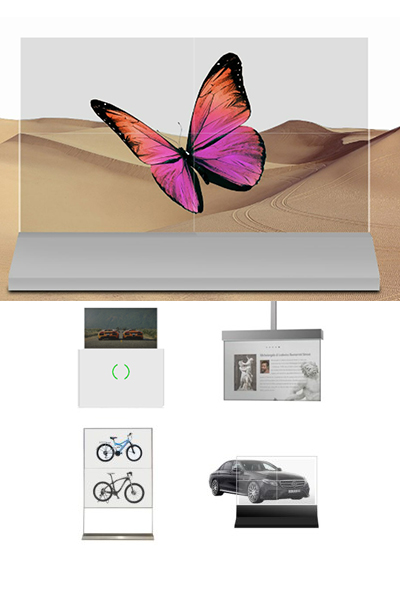

PRODUCT SERIES

PRODUCTS

ABOUT US

COMPANY PROFILE

Countries and regions are covered

100+

Researchers are employed

30+

Devices sold worldwide

600000+

Provide odm/oem services

200+

Successful cases

Solutions

In the demanding environment of industrial automation, industrial control computers are the backbone of various processes. These systems are highly sensitive to electrostatic discharge (ESD), which ca

In the realm of industrial automation, industrial control computers play a pivotal role in managing and monitoring critical processes. These systems often rely on backup batteries to maintain essentia

In industrial environments where continuous operation is critical, industrial control computers often incorporate redundancy components to enhance system reliability and minimize downtime. Redundancy

In the complex landscape of industrial automation, industrial control computers serve as the backbone, orchestrating critical processes and ensuring seamless operations. However, like any sophisticate

In the realm of industrial automation, industrial control computers play a pivotal role in managing and monitoring complex processes. These systems rely heavily on robust communication links to exchan

In industrial automation systems, the accuracy of input/output (I/O) channels in industrial control computers is paramount. These channels serve as the vital link between sensors, actuators, and the c

Industrial control computers are the backbone of numerous industrial operations, managing and regulating complex processes. The power module is a critical component that supplies stable electrical ene

Industrial control computers are the nerve - centers of many industrial operations, managing and monitoring complex processes. Their interfaces, whether they are physical connectors, ports, or touch -