Welcome STARK TOUCH DEVICE!

Intelligent manufacturing

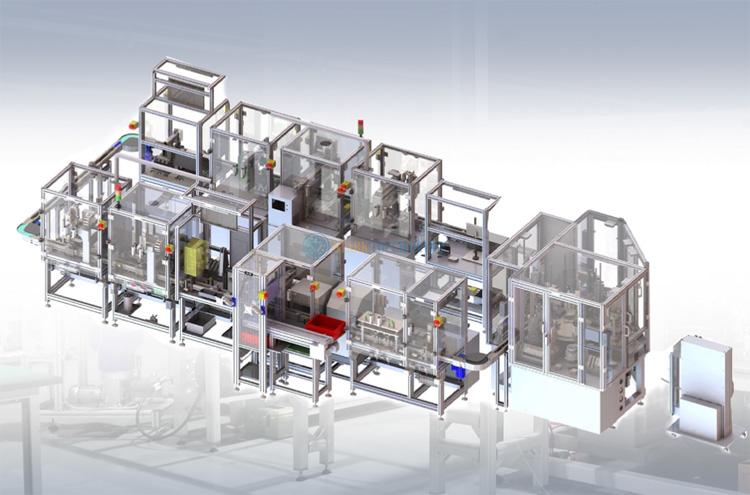

Application of Industrial Display Solutions in Automotive Assembly Lines

I. Industry Development Background

Behind the booming automotive industry lies a sophisticated production and assembly system. From components to complete vehicles, the manufacturing processes have grown increasingly complex, necessitating a surge in automated assembly and inspection equipment.

II. Project Application Overview

Industrial displays facilitate automated production, quality inspection, and process monitoring on automotive assembly lines, ensuring productivity, quality, and cost reduction. A leading automation equipment manufacturer deployed embedded industrial displays for its automotive parts assembly and testing equipment. These robust displays, with large screens, play a pivotal role in information insight and control interaction, enabling operators to respond swiftly and adjust equipment flexibly.

III. Product Solutions

Given the diversity of automotive assembly processes and various automated production lines, the project adopted 12", 15.6", 17.3", and 19" TPC-M2 displays, all operating efficiently and reliably.

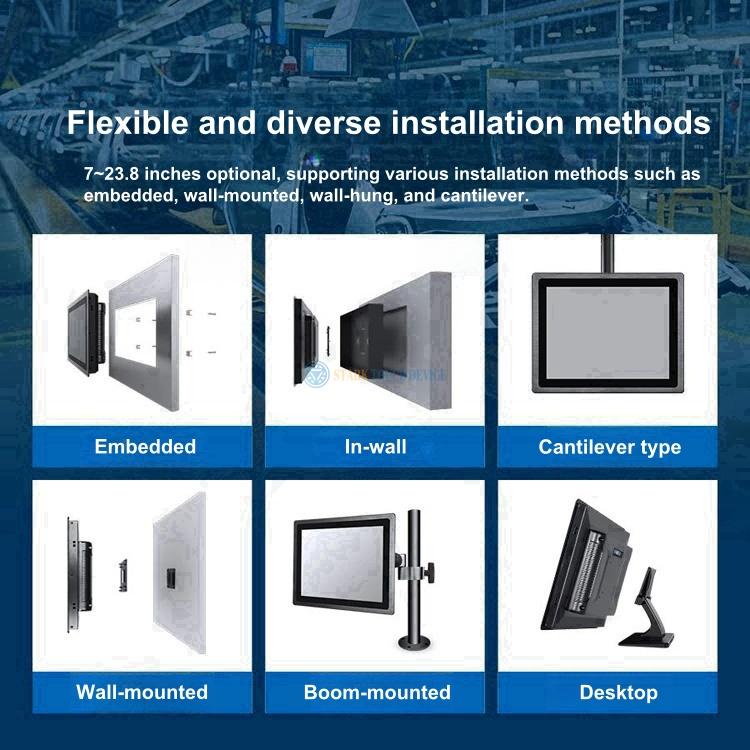

Flexible Integration for Enhanced Efficiency

With sizes ranging from 7" to 23.8" and versatile mounting options (embedded, wall-mounted, arm-mounted, etc.), industrial displays seamlessly integrate with all automotive assembly automation equipment, catering to workshops of various sizes for more convenient and efficient applications.

High-Precision Multi-Touch Technology

Featuring 10-point capacitive touch technology for lag-free control, industrial-grade panels offer FHD resolution, high brightness, 178° viewing angles, and glove-touch capabilities, ideal for centralized management and displaying critical assembly data.

Rugged Industrial-Grade Design

Constructed from high-strength, lightweight, heat-conductive, and anti-interference aluminum alloy, with metal brushing and die-casting for industrial aesthetics and structural stability, the displays house military-grade components within a sealed, shock-absorbing design. They withstand mechanical impacts, moisture, dust, EMI/EMC interference, and temperature fluctuations, ensuring durability and reliability.

Stability-Focused Connectivity Optimization

Addressing voltage fluctuations, poor contact, and loose connections, the displays employ DC12V-36V wide-range input and secure DC connectors with threaded anti-detachment, while RJ45 pins lock touch interfaces for reliable connections, ensuring stable and efficient production line operations.

IV. Industry Development Insight

Equipped with proprietary industrial-grade driver boards, these displays cater to diverse industry needs, offering universal compatibility and facilitating rapid project deployment. Leveraging robust R&D resources and direct production-sales chains, they offer bulk purchases and flexible customization, precisely meeting customer demands with cost advantages.