Welcome STARK TOUCH DEVICE!

Intelligent manufacturing

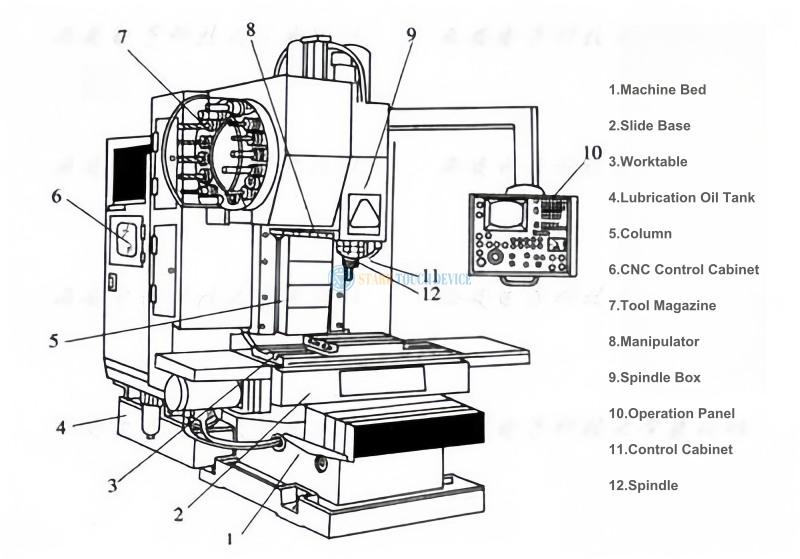

The Application of Embedded Industrial All-in-One PC in CNC Machine Tools

System Overview:

CNC (Computer Numerical Control) machines are automated machine tools equipped with a programmed control system. They adhere to predefined programs of control codes and symbolic instructions, precisely machining parts as per production drawings. These machines excel in tackling complex, precise, small-batch, and multi-variety part processing, embodying the cutting-edge direction of modern machine tool technology. Fully automated CNC machines drastically reduce labor costs, executing predetermined programs with minimal input, ensuring high efficiency, low error rates, and stable long-term operation. The operation and monitoring of CNC machines are entirely managed through the control terminal, serving as the "brain" of the system, underscoring its paramount importance. Our industrial all-in-one computers play a pivotal role in this "brain" for CNC applications.

System Requirements:

CNC machines integrate cutting-edge technologies from mechanics, automation, microelectronics, and more. Essentially, they operate as a human-machine interface system, where control panel inputs, programming, encoding, and decoding orchestrate the entire machine to produce various parts. The choice of control terminal significantly impacts the application efficiency and user experience of CNC machines.

Powerful Processing System: Required for handling intricate production programs.

Stable Performance: Ensuring uninterrupted production processing.

Low Power Consumption & Maintenance Costs: Prolonging service life.

Expandable Interfaces: For integrated control of other production equipment.

Environmental Resilience: Resistant to electromagnetic interference, dust, shock, water, and static electricity.

Flexible Installation: Tailored to CNC machine specifications.

Versatile Touch Screens: Catering to diverse user preferences.

Solution:

Our industrial all-in-one computers fulfill the "brain" requirements of CNC machines during production. Equipped with industrial-grade components and proprietary boards, our smart industrial all-in-ones boast robust performance with an MTBF (Mean Time Between Failures) of 5000-8000 hours. They support various software applications and programming necessary for CNC production. The rugged metal casing offers dust, vibration, and interference resistance, enhancing overall system stability. Data acquisition and analysis facilitate intelligent, optimized machine control. Front panel features like reset buttons, hard disk indicators, and power switches enhance operator control, directly improving efficiency and comfort.

Industrial All-in-One Computer Features:

Windows/J1900/4G+32G Configuration

Industrial-Grade Components & Proprietary Boards

EMI/EMC Compliant Internal Design

Customizable Front Indicators, Manual & Automatic Reset Buttons

MTBF up to 5000-8000 Hours

Extensive I/O Ports for Device Expansion & Subordinate Machine Control

Intuitive & Swift Operation Interface

Multiple Installation Options Tailored to Automation Sites