Welcome STARK TOUCH DEVICE!

Intelligent manufacturing

Application of Android PC in production line workstations

Industry Background

Manufacturing, the lifeblood of a nation's economy and the cornerstone of the real sector, stands at a pivotal juncture amidst the rapid advancements in information technology and the digital economy. To rebound from the blows of the traditional economy and transcend outdated production models, the manufacturing industry must expedite its integration into the digital and automation revolution, aiming for dual enhancements in efficiency and profitability.

Industry Application Needs

As a critical aspect of manufacturing management, the digital transformation of production lines has garnered increasing attention. The production line Kanban board, a vital tool for visualizing production processes, is increasingly utilized in smart manufacturing site management. By presenting data and images, it enables frontline workers and managers to grasp production status intuitively, thereby boosting efficiency.

However, conventional Kanban boards, reliant on static displays like video walls or LCD screens, fall short in providing interactivity or enabling data interconnection, information exchange, and production collaboration across workflows.

Enter the era of Android Industrial PCs, which emerge as innovative solutions, addressing the limitations of traditional Kanban boards. These devices showcase real-time production status and related information, facilitating information flow and human-machine interaction across production segments. They also empower more sophisticated and intelligent data analysis and management forecasting capabilities.

Android Workstation Devices in Action

Android workstations, exemplary and widely applied in production line Kanban systems, offer foundational display capabilities with multiple expanded functionalities:

Real-time Display: Equipped with high-specification industrial LCD screens of various sizes and IP65-rated dust- and waterproof front panels, these workstations cater to diverse production environments. Integrated with software, they display production orders, material flows, process statuses, and fault warnings, empowering workers to swiftly comprehend their stations and adjacent workflows, fostering prompt responses that enhance productivity and quality.

2.Information Interaction: Boasting RK3288 self-developed industrial-grade Android motherboards, Intel quad-core processors (up to 1.8GHz), and compatibility with Android/Linux/Ubuntu/Debian, these workstations enable customized development for seamless human-machine interfaces. Agile capacitive touchscreens facilitate task browsing, production registration, and SOP-driven training and guidance, enhancing management efficiency.

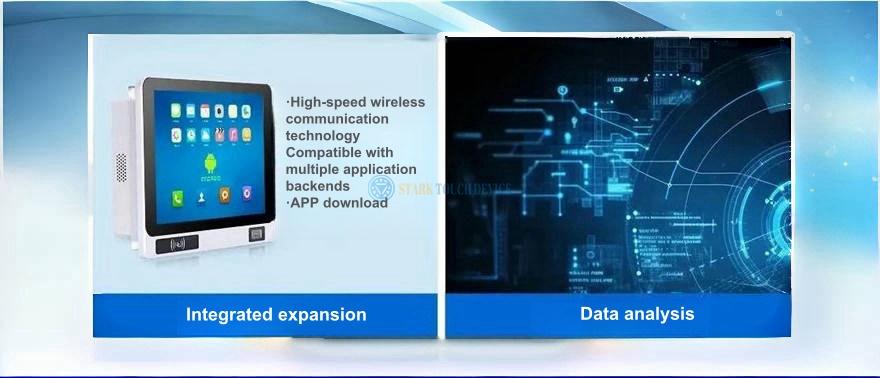

3.Integration & Expansion: With dual Gigabit Ethernet, 4G/5G, WiFi, Bluetooth, and support for numerous apps and enterprise backends (ERP, MES, smart manufacturing systems), Android workstations facilitate attendance tracking, access control, and data interconnectivity. Rich expansion ports cater to unique application requirements.

4.

Data Analysis: With up to 8GB+64GB storage and AI-powered data processing, these workstations collect and analyze big data from automated production, providing real-time insights for data-driven management decisions.

Designed with aesthetic appeal and versatile mounting options, Android workstations thrive in wide temperature and voltage ranges, EMI/EMC shielding, and shock resistance (GB2423). Reliable and powerful, they find applications in smart manufacturing, smart cities, healthcare, and AI.

In the realm of industrial touch displays, we relentlessly pursue a vision of expansive smart connectivity, crafting high-value digital solutions. Through relentless product and quality enhancement, we continuously create value for clients, driving towards an interconnected future.