Welcome STARK TOUCH DEVICE!

Intelligent manufacturing

Application of Smart Industrial All-in-Ones in Metal 3D Printers

1. Industry Development Background

3D printing, also known as "additive manufacturing," is an advanced manufacturing technique that builds three-dimensional objects from digital models through layer-by-layer material deposition and solidification. With the disruptive advancements in aerospace, scientific research, healthcare, and automotive precision industries, the demand for high-strength, high-precision, lightweight, and flexible metal parts has become increasingly urgent. As a result, 3D printing has gradually shifted its focus from polymeric materials to metal powders, driving the expansion of the metal 3D printer market. Fueled by Industry 4.0 technologies, this sector has entered a new era of intelligent and digital development.

2. Equipment Support Needs

Metal 3D printers are equipped with advanced sensor and functional systems such as print heads, scanners, feeders, and cooling mechanisms. The coordinated operation of these systems relies heavily on robust core control, data monitoring, and interactive interfaces. Leveraging the reliable performance of industrial all-in-ones is crucial to enhancing the operational efficiency of metal 3D printers.

Selecting and configuring all-in-ones for metal 3D printing necessitates considerations like computational power, hardware configuration, and industrial-grade reliability for extended runtimes, resilient to temperature fluctuations, humidity, vibrations, and voltage spikes in specialized environments.

3. Product Solutions

Drawing on over a decade of technological expertise, we have independently developed industrial all-in-ones, monitors, and motherboards tailored for metal 3D printers, offering premium hardware specifications and stable operation.

Visual Interaction: High-grade industrial LCD screens provide precise visuals and easy readability, customizable for brightness, contrast, viewing angles, and touch interfaces. Through the touchscreen, users can effortlessly set print parameters, monitor progress, and make necessary adjustments.

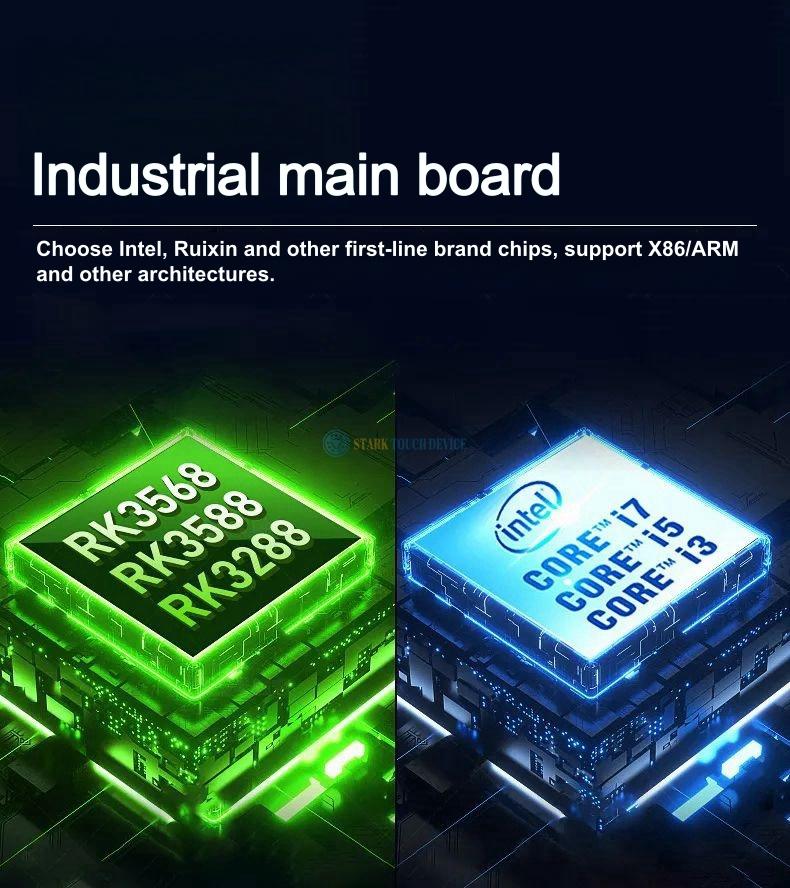

High-Performance Computing: Equipped with proprietary high-performance control boards, featuring Intel, Rockchip, and other top-tier chipsets, our all-in-ones boast multi-core processors for robust AI-driven computing, efficiently supporting sensor control, intensive computations, and data processing in metal 3D printing, ensuring ample power for high-speed printing.

Extensive Software Compatibility: Adopting mainstream X86/ARM architectures, our all-in-ones run Windows, Android, Linux, Ubuntu, Centos, and integrate seamlessly with professional 3D modeling, slicing software, and customer MES systems for customized applications.

Storage & Networking: With up to 8GB+64GB storage (ARM-based), USB expandability, Gigabit Ethernet, WiFi 6, Bluetooth, and optional 3G/4G/5G connectivity, our all-in-ones enable remote control, multi-machine management, and seamless data communication.

Industrial-Grade Protection: Meeting wide temperature (-10°C~60°C) and voltage (DC 12V-36V) standards, our products are certified for vibration resistance (GB2423), EMI/EMC interference protection, IP65 water/dustproofing, and ESD protection, ensuring 7x24-hour stable operation in harsh industrial environments.

4. Application Empowerment

Our industrial control products have been successfully integrated into numerous metal 3D printer applications. Leveraging our robust R&D resources and technical prowess, we offer personalized services like appearance customization, configuration upgrades, module additions, software tuning, and system development, empowering clients to differentiate their products, shorten development cycles, and maximize business value.