Welcome STARK TOUCH DEVICE!

Intelligent manufacturing

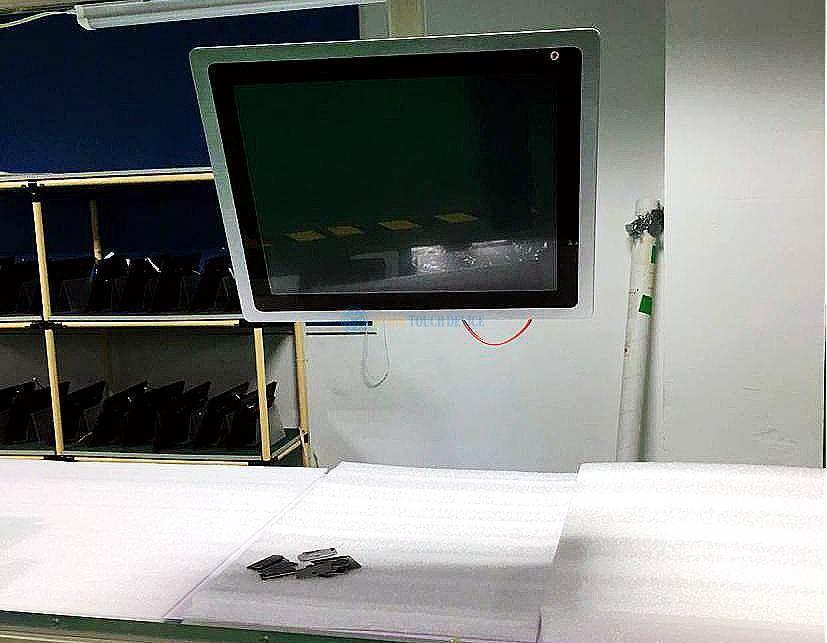

Application of Industrial Android All-in-One Machines in Workshop SOP Stations

System Overview:

Workshop SOP stations serve as a vital coordinating tool, orchestrating the production pace and efficiency across the entire manufacturing floor. They enable remote design and execution of work instructions, display contingency plans, and facilitate remote control of displays, allowing for seamless adaptation to production line changes through the replacement of images across various points. The implementation of Workshop SOP stations not only enhances production line efficiency significantly but also mitigates the idleness and waste of production resources. Our intelligent industrial Android all-in-one machines excel in this application, functioning as both visual dashboards and management terminals that standardize, scientize, and institutionalize workshop management.

Equipment Requirements:

Widely adopted in modern production lines, Workshop SOP stations necessitate seamless information communication between management centers and workshop production lines, facilitating functions such as deployment management, message inquiry, station alerts, and production order releases. These systems must offer instant access to system management, information display, and communication, ensuring a seamless user experience.

Rugged Design: Capable of withstanding complex production environments, including dust, water, and electromagnetic interference.

Stability & Durability: Guaranteed long-term operation with low power consumption and high mean time between failures.

User-Friendly Interface: Flexible touch interaction, simple UI design, and ease of operation.

Versatile File Support: Compatible with PDF, JPG, DOC, XLS, MP4, and other file formats.

Advanced Authentication: Supports facial recognition, RFID card reading, and QR code scanning.

Integration with Smart Factory Systems: Capable of running MES/SIP (Manufacturing Execution System/Supervisory Information Platform).

Extensibility: Pre-equipped with multiple interfaces for external device connectivity, SDK packages for secondary development.

Solution:

Our intelligent industrial Android all-in-one machines feature a proprietary industrial-grade RK3399 Android motherboard, designed for 7*24h unmanned high-load operation. With a military-grade aluminum alloy construction, fanless and noiseless design, they excel in dusty, vibratory, high/low-temperature environments, thanks to their efficient heat dissipation system. The capacitive touchscreen supports ten-point multi-touch for intuitive, engaging, and durable operations, compatible with resistive touch as well. These machines can be expanded with multifunction modules to cater to diverse system management needs in production lines. Additionally, they offer upgrades for features like attendance systems, RFID recognition, video linkage capture, and intrusion alerts, integrating stability, security, and simplicity to effectively upgrade entire workshop management systems.

Device Capabilities:

Integrated Components: RK3399 Android motherboard, card reader, infrared sensor, camera, digital buttons, fingerprint scanner, ambient light sensor.

Rugged Construction: Explosion-proof, waterproof, and dustproof, ideal for industrial settings.

Advanced Touchscreen: Capacitive ten-point touch technology, compatible with resistive touch.

Enhanced Security: Face recognition with dual 200W wide-dynamic-range live cameras for dual-layer protection.

Scanning & Reading: Barcode/QR code scanning and RFID card reading capabilities.

Open Software Interface: SDK provided for secondary development and debugging.

Smart Factory Integration: Compatible with MES/SIP management systems.

Versatile Connectivity: Equipped with a range of input/output interfaces for seamless integration with various devices.