Welcome STARK TOUCH DEVICE!

Smart city

Transforming Industries with Digital Innovations: Stark's Role in Smart Manufacturing & Urban IoT

The digital revolution is reshaping our world at an unprecedented pace. Today, the total number of connected devices surpasses the global population, generating vast amounts of data that transform both life and business. This intelligent infrastructure propels urban development, fuels economic growth, and enhances cities and businesses' efficiency, competitiveness, and resilience to emergencies. The Internet of Things (IoT), in conjunction with automation, artificial intelligence (AI), and cloud computing, is truly transforming traditional industries into smart manufacturing hubs.

At the forefront of this transformation, trends like digital twins, human-machine interaction, predictive maintenance, cybersecurity, resilience, automation, and edge computing are emerging as key drivers of smart manufacturing. These trends significantly redefine relationships between machines, humans, predictions, and operations, propelling our era forward.

Stark stands at the vanguard of this digital evolution, specializing in self-service terminal services and providing solutions for urban IoT hardware and software development. We enhance cities' comprehensive service systems by delivering innovative products and services.

1. Innovative Human-Machine Interfaces

While computer screens and conventional displays still dominate industrial settings, the landscape is shifting. Augmented Reality (AR) applications offer invaluable feedback when inspecting equipment components, providing IoT-derived insights to streamline management and maintenance. Virtual Reality (VR) similarly empowers workers with powerful visualizations, tailored to specific tasks. With the increasing affordability and popularity of headsets and smart glasses, these technologies are poised to become even more prevalent in industrial environments.

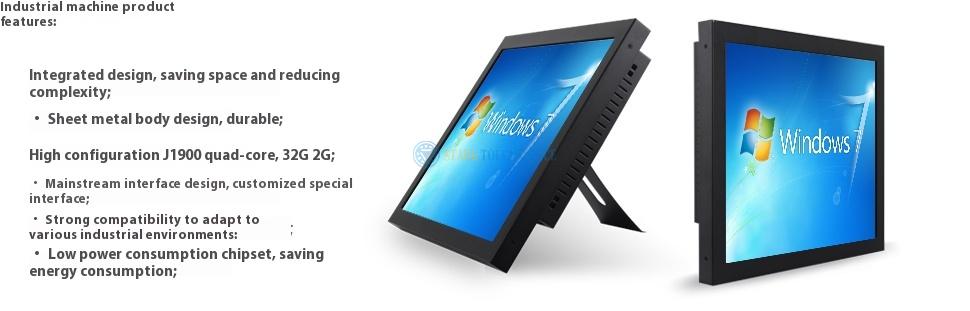

Stark embraces this innovative spirit, infusing it into our company culture and product development, exemplified by our in-house developed driver boards, motherboards, and industrial displays. We optimize designs, enhance functionalities, and tailor solutions to meet diverse customer needs.

2. Enhanced Predictive Maintenance

Predictive maintenance has grown increasingly crucial in industrial settings, and the proliferation of IoT components provides more data than ever before. Integrating machine learning and other AI tools, modern industrial software now outperforms human judgment in determining when to replace equipment parts. The benefits of predictive maintenance are tangible, making it a valuable ally for future industrial managers.

3. Secured Networks

In the early days of IoT, security was often overlooked, leading to chaotic executions. However, the tide is turning as companies investing in IoT prioritize safeguarding their investments from cyber threats. The rising frequency and profitability of cyberattacks, coupled with the vulnerability of unsecured industrial devices, necessitate robust security measures.

Manufacturers face the challenge of ensuring compliance with security regulations, as there's no one-size-fits-all solution to fully protect against breaches. Stark prioritizes security in our solutions, helping clients navigate this complex landscape.

4. Flexible Transitions

Due to high downtime costs, industrial enterprises often avoid hardware and software upgrades, leading to sluggish transformation. However, the pursuit of efficiency necessitates more flexible operations. IoT and AI analysis uncover hidden correlations that humans might overlook, accelerating the long-term transformation of the industrial sector.

5. Efficient Automation Technologies

Automation has always been central to industry, and digital technologies are expanding this trend. Businesses can now augment extensive manufacturing components with low-cost devices, reducing reliance on expensive heavy machinery. As automation systems continue to demonstrate their value, enterprises will invest more, resulting in significant efficiency gains and lower labor costs.

6. Timely Edge Computing

The sheer volume of data generated by IoT components necessitates real-time monitoring. Edge computing devices collect, process, and analyze data before transmission to centralized servers, alleviating bottlenecks in IoT applications. While investments in servers and cloud solutions will continue, edge devices will see significant growth, mitigating processing pressures in today's industrial environments.